Download Brochures

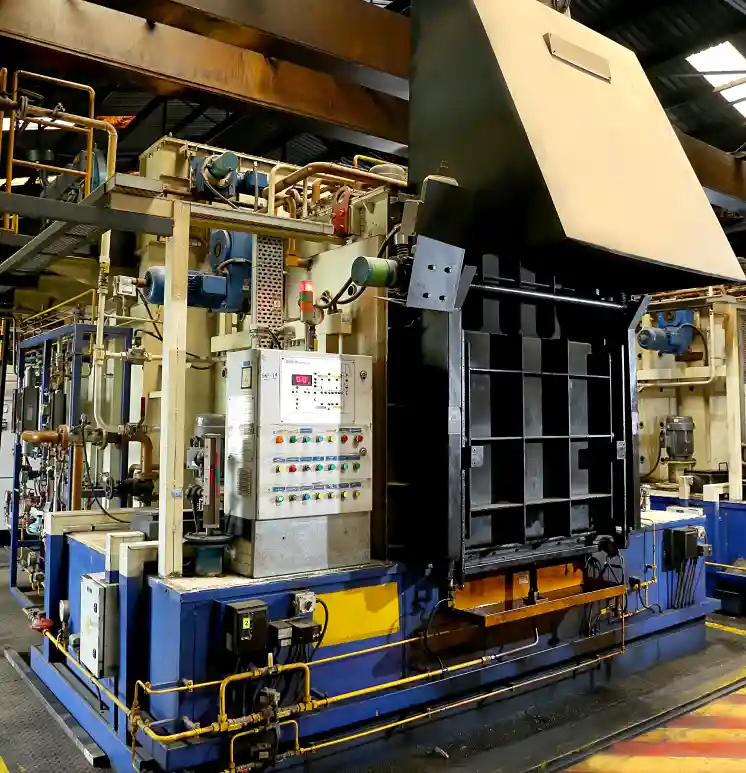

Unlocking Superior Surface Performance for Your Components!

Unlike traditional carburising methods, carbonitriding performs the process at lower temperatures, ranging from 870 to 880 degrees Celsius, and in shorter times. This results in exceptional surface hardness and durability!

Carbonitriding minimizes distortion and warping in components that usually occurs with other hardening processes. With carbonitriding, all components remain true to their original form, ensuring a seamless fit and perfect functionality.

We offer case depths ranging from 0.1 mm to 0.6 mm, to ensure the ideal balance of strength and flexibility.

Steel Grades

216MnCr5, 20MnCr5, SAE 52100, Sintered parts etc…

Applications

Applications

Grears & Shafts

Rollers & Bearing

Synchro rings

Sintered parts

Download Brochures