Download Brochures

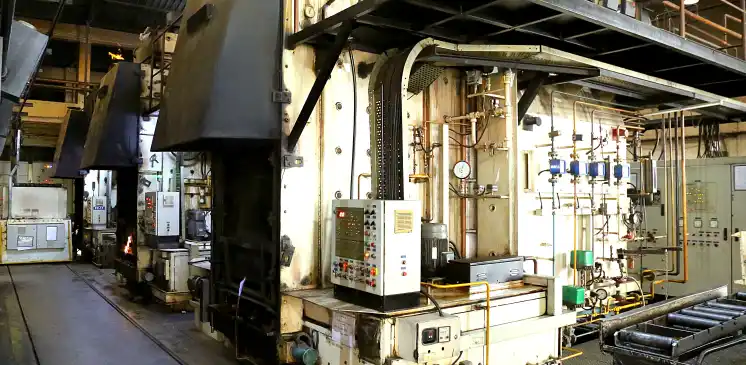

The Ultimate Surface Hardening Process for Low Carbon Steels!

Carburizing is a highly effective case hardening technique that infuses carbon into solid ferrous alloys to significantly boost its surface hardness.

We carefully heat metal parts in a carbon-rich atmosphere, above the transformation temperature, for a predetermined time. This critical step ensures that the carbon thoroughly permeates the metal, creating a robust carburizing layer on the surface.

Additionally, to achieve the ultimate hardness, the carburized components undergo a quenching process, further reinforcing the surface layer and solidifying its strength.

We guarantee case depths ranging from 0.3 mm to 3 mm!

Steel Grades

20MnCr5, 16MnCr5, SAE 8620 H, SAE 8625 H, EN 353, 25CrMo4 SCM

420, SCM 415

etc…

Applications

Transmission components

First, second & third stage gear

Pinion

Input shaft

Output shaft

Balance Idler

Sprag Clutch

Gear Oil Pump Drive

CV Cage

Differential Spider

Engine Components

Crank Pin

Piston rockshaft

Engine Components

Inner ring

Needle roller bearing

Outer ring

Plunger

Download Brochures